A Summerland farmer who created the world╬┌Đ╗┤ź├Ż first non-browning apple has a new plan to use genetic engineering, robotics, and AI to dramatically reduce the number of people needed to work on a farm.╠ř

Neal Carter hopes to create an apple tree that produces fruit at a single height that would allow for swift mechanical harvesting. Labour costs currently account for 60 per cent of an apple farm╬┌Đ╗┤ź├Ż operating costs, he says.╠ř

ÔÇťEscalating labour costs are the primary challenge to the continued viability of the U.S. apple industry,ÔÇŁ says Carter, co-founder of Okanagan Speciality Fruits. ÔÇťA radical transformation is necessary for the industry╬┌Đ╗┤ź├Ż survival.

ÔÇťOrchardists everywhere are facing similar challenges that demand bold and timely solutions,ÔÇŁ Carter says.╠ř

Carter developed Arctic Apples, a variety that does not brown when the fruit is sliced. While the company is still based in Summerland, it was acquired by an affiliate of Third Security, LLC in 2019 and Arctic Apples are grown and processed around Moses Lake, WA.╠ř

Washington State is by far the biggest producer of apples in the U.S., with an annual crop of 179 million bushels worth $2B (U.S) The Washington State crop accounts for two-thirds of all apples grown in the U.S.

But the industry south of the border is plagued by many of the same issues familiar to Okanagan growers, such as low market prices, extreme weather, and soaring costs for fuel, fertilizer, and labour.

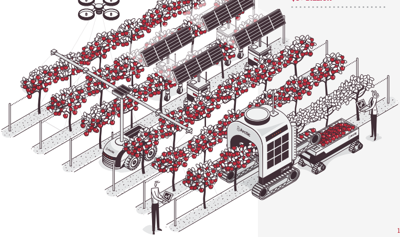

Carter outlined his plan for the fruit industry to make a sweeping embrace of genome editing, robotics, and AI in a white paper called ÔÇśTraits and Tech: Designing the Orchard of the FutureÔÇÖ. He also expounded on the vision during symposiums on agricultural innovation held April╠ř30 at Big Bend Community College, which included demonstrations of how AI and robotic-like tools can be used in orchards.╠ř

By altering an apple tree╬┌Đ╗┤ź├Ż germplasm, Carter says, its fruit can be produced at a single height. That would facilitate the nearly full automation of production and harvesting through robotics and AI, he says.╠ř

ÔÇťThese changes will significantly reduce production costs, support sustainable agricultural practices, and ensure the industry╬┌Đ╗┤ź├Ż continued economic viability,ÔÇŁ he says. Projected savings of about $9,000 an acre could be achieved over current production costs of about $15,000 an acre, he says.╠ř

Some other recent developments in the apple industry - such as increasing the density of tree plantings and developing new dwarfing rootstocks - have actually increased the overall cost of production, Carter says.╠ř

ÔÇťImproved genetics represent the industry╬┌Đ╗┤ź├Ż only real option to implement a market-disrupting, game-changing system that can effectively reduce the high labour demands that are economically unsustainable,ÔÇŁ he says.╠ř

Quick Facts

- Up until the late ÔÇś70s, commercial apple orchards had a density of about 100 trees per acre. Farmers could spend an entire day pruning one tree

- To boost efficiency, higher-yielding varieties and different planting strategies were introduced. Some U.S. farms have as many as 2,400 trees per acre.╠ř

- Summerland orchardist Neal Carter envisions a ÔÇśfarm of the futureÔÇÖ with about 1,800 apple trees per acre, but with all the fruit grown at a standard height and harvesting done through a combination of AI and robotic technology.╠ř